DescriptionPolyvinyl alcohol(PVA) fiber is designed for use in cement mortar or concrete to increase the internal quality, reduce maintenance cost and prolong service life of cement mortar and concrete. It can reduce the formation of shrinkage cracking in cement mortar and concrete prior to the curing process and increase their toughness.

It is produced from polyvinyl alcohol as main raw material by a process of dissolution, spinning, heat-setting, cutting and baling to form a high-strength, high-modulus fiber. PVA fiber can disperse quickly and easily in the mortar and concrete mix after being added into the base materials, the fiber can form a randomly oriented support system in concrete which can effectively control the formation and development of non-structural cracking such as plastic shrinkage cracking and drying shrinkage cracking, effectively reduce the segregation of aggregate and the formation of settlement cracking.

Features

- High strength and low elongation

- Acid and alkali resistance: less strength loss than any other fiber at high temperature for extended period.

- Light resistance: greatly less strength loss than other fibers after a long period of sun exposure.

- Corrosion resistance: no mildewing, rotting and wormed damages after a long period of burial in dirt.

- Dispersion: no adhesion, rapid dispersion in water, good compatibility with cement.

- Non-toxic and pollution free

Uses

Reinforced cement materials. The fiber has a high tensile strength and good dispersive performance, non-toxic and pollution free with high resistance against corrosion, worms and daylight. It can be widely used in cement products, road construction, water conservancy project and the like.

* Replaces asbestos to produce high-strength cement products

* Applied to road construction, especially high grade highway construction.

* Can be used in water conservancy construction, replacing steel bar as lacing wire.

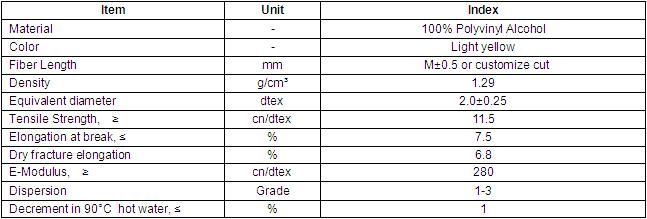

Physical Property

Note: M denotes 3mm, 6mm, 9mm, 2mm, 15mm.

Waterproof membranes

Waterproof membranes Geosynthetics

Geosynthetics Industrial films and fibers

Industrial films and fibers

Polyvinyl Acohol(PVA) Engineering Fiber

Polyvinyl Acohol(PVA) Engineering Fiber