Waterproof membranes

Waterproof membranes Geosynthetics

Geosynthetics Industrial films and fibers

Industrial films and fibers

Biaxial Polypropylene(PP) Geogride

Biaxial Polypropylene(PP) Geogride Download

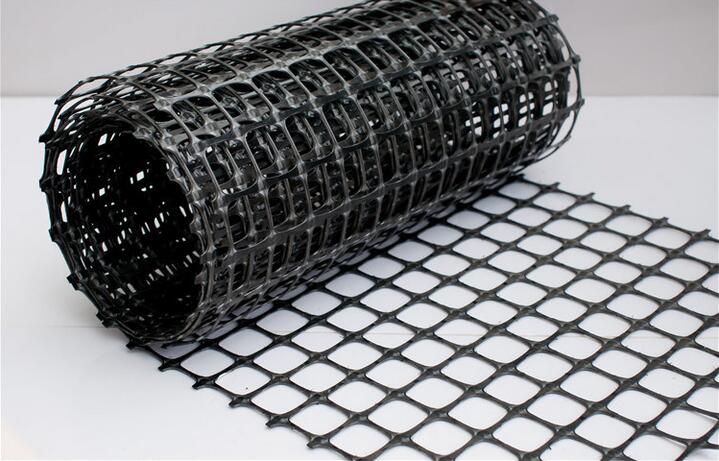

Download Biaxial Polypropylene(PP) Geogrid uses polypropylene (PP) as raw materials and are produced by a process of extruding, punching, heating, and longitudinally and laterally stretching. In this process polymer molecule is distributed a linear state from chain shaped and long oval network structure, which fully provide the high flexural rigidity and tensile strength along the ribs and at the junctions that war required for long-term interlock and confinement. The geogrid can carry high tensile loads applied in longitudinally and horizontally directions. Their open aperture structure interlocks with fill material to provide superior load transfer from soil to geogrid, an efficient stress transfer can be spread the load to a larger area of the soil quickly and effectively.

Features

☆ High tensile strengths and junction efficiency

☆ Flexural rigidity and aperture stability

☆ Resistance to biological degradation and chemicals, long service life

☆ Weathering resistance from UV degradation

☆ Resistance to environmental stress cracking

☆ Enlarge road loadings,enhance the life of road

☆ Excellent loading change and prevent roads from cracks and deformation, minimize rutting

☆ Convenient construction, low costs

Uses

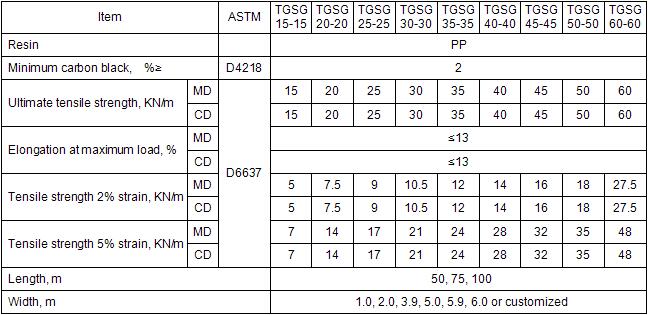

Soft foundation and stabilization and reinforcement for paved highways androads, runways, railways, dams, bridges, steep slopes, parking lots, mining and tunnel. As gabions for wall construction, erosion control structures and bridge abutments. Reinforcing on weak subgrades such as soft soils, peat, tundra. Net work for animal and husbandry, and cage fishing.Type andSpecification: GB/T17689-2008